Understanding Creep

Overview

Creep is a material property frequently misunderstood and can be defined as the continued extension of a material when subjected to constant, long-term static loading. For a rope product, creep is the length or rate at which the fibers in the rope stretches irreversibly over time. Creep should not be confused with constructional elongation as creep relates to the fiber in the rope, NOT to rope construction.

All synthetic fibers exhibit some degree of creep and not all irreversible elongation of a new rope is due to creep (constructional setting, splice slippage, etc). Typically creep will require that ropes be re-tensioned as the elongation increases and/or line tension decreases. However, as the rope creeps under tension, it will eventually stretch to a point of complete failure called creep rupture. Due to this potential failure, creep should be one of the main concerns for applications that require long-term static loading (e.g. permanent offshore oil platforms). However, it should be noted that most rope applications are not subjected to constant loads and therefore creep is not relevant.

FOR EXAMPLE Creep would be a factor in a permanent guy-wire installation such as for antenna towers, but not in dynamic applications such as ship mooring or utility winch lines where ropes are being flexed/re-flexed on a regular bases.

The Phases of Creep

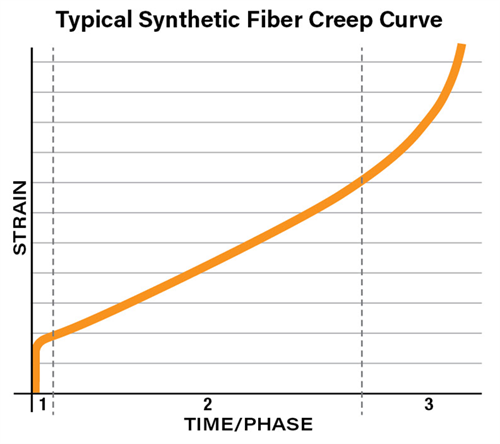

The creep process of synthetic fibers has three distinct phases;

- In phase one, the rope undergoes rapid elongation (a few percent) immediately after the load is applied and may continue this rapid elongation from a few minutes to a few hours. During this primary creep phase, the line will have to be re-tensioned periodically. It should be noted that this “primary” creep is reversible.

Note: Primary creep is in addition to initial constructional elongation which is due to rope compaction as the fibers and strands align and adjust under load. - In phase two, the rope undergoes a slow, steady rate of elongation (a few percent per year assuming a constant, static load). During this secondary creep phase, the line may have to be re-tensioned periodically over the service life of the line (years).

- In phase three, the rope undergoes rapid elongation that ultimately ends in line failure. Typically, the line is retired before entering this tertiary creep phase.

Creep process has three distinct phases.

As mentioned previously, resistance to creep is a critical design consideration in material selection for many applications requiring constant, long-term dimensional stability such as bowstrings, permanent mooring lines, and robotic tendons. And while creep is affected by many factors including materials properties, temperature, load, and duration (time), the ultimate decision maker is time. Creep is a time-dependent phenomena and the decision-maker between using a “regular” HMPE fiber like Dyneema® SK75 or a “lower creep” fiber like SK78 is dependent upon the service life.

FOR EXAMPLE Brad Van Liew requires a new main halyard for the Le Pingouin

(a 60 foot racing sailboat) and is trying to decide if the line should be made of Dyneema® SK75 or SK78. Let’s compare the situations:

- As SK75 and SK78 are virtually identical fibers, the lines will be exactly the same in terms of dimensions, weights, strengths, feel, and handling.

- Both ropes will require an initial “break-in” period while the ropes work their way through primary creep. This would involve periodic re-tensioning of the line over the course of a few hours to a few days (load dependent).

- Assuming the lines are tensioned to 20% of the rated breaking strength, the SK75 line would creep ~0.1% per month and have to be retired in about 8 years. The SK78 line would creep at about a third of the rate, or ~0.033% per month, and have to be retired in about 24 years. Of course, these service lives are based on the assumption that the lines are under continuous tension (for the entire service life) and are not subjected to other forms of wear (i.e. abrasion).

Both lines would perform equally well and allow the Le Pingouin to compete in several Velux 5 Oceans Races.

In summary, creep is a time-dependent irreversible elongation of the rope and is only a concern if:

- The line is under long-term static loads, and

- The service life of the line is on par with the creep life of the fiber.