Knot Adjustment under Extreme Tension

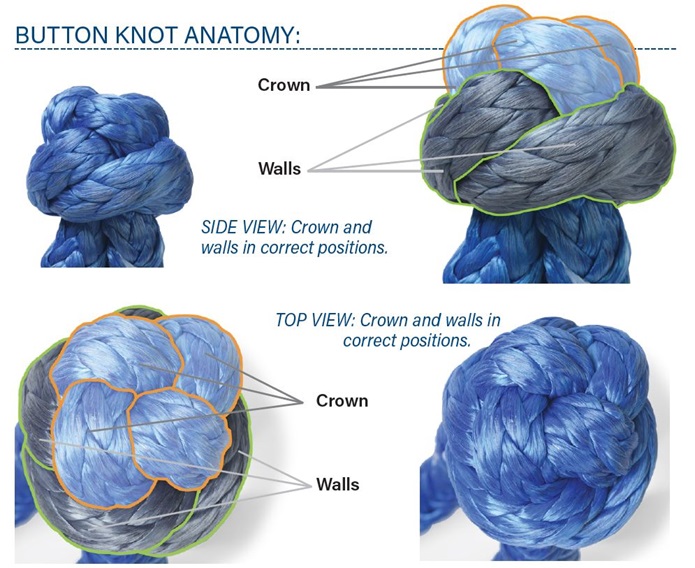

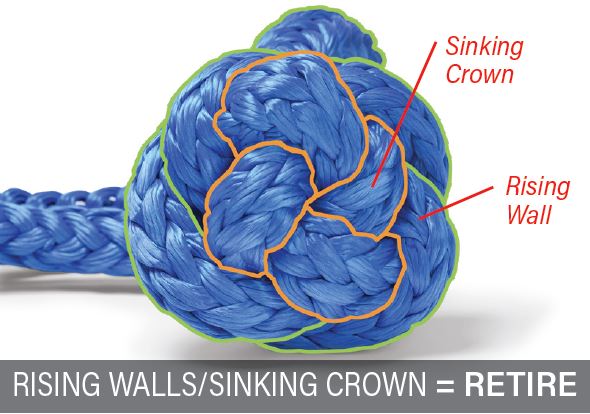

When a Link-It or Link-It Plus experiences a high level of tension, the knot adjusts as the rope sections within the knot compress and reduce in diameter. This initial knot adjustment helps to stabilize and secure the knot for long-term use. However, excessive knot adjustment can occur under extreme loading (>40% of Minimum Breaking Strength) during initial use. Excessive knot adjustment can be identified by the sinking of any of the four crowns at the top of the knot, or rising of any of the four walls that make up the knot’s base. The peak of a sinking crown will be 1–2 rope diameters lower than other crowns. A rising wall moves above the halfway point and threatens to slide over a crown. If either a sinking crown or rising wall is identified, the Link-It must be retired. Refer to the provided photos to identify the knot anatomy and learn the signs of excessive knot adjustment.

WHAT: Walls rising around crown top view.

CORRECTIVE ACTION: Damage permanent, retire.

WHAT: Crown sinking into walls side view.

CORRECTIVE ACTION: Damage permanent, retire.

Link-It Plus Chafe Sleeve Inspection

Link-it Plus includes added chafe protection which acts as a sacrificial barrier and extends the lifetime of the product. Damage or wear to the chafe protection does not affect the strength of Link-it Plus but is a good indicator for “hot spots” where the rope is likely to see abrasion and wear over time. For any guidance, reach out to your Samson representative.

WHAT: Chafe section that has been worn through over time during normal use.

CORRECTIVE ACTION: Check rope underneath the damaged chafe. Inspect and repair.

WHAT: Rope wear that occurred after the chafe was worn through.

CORRECTIVE ACTION: Inspect rope. Shift the chafe to cover rope's typical bearing surface.

Holistic Approach to Damage Assessment

Samson takes safety seriously and cares about supporting safe operations. Samson thrives on providing products and innovations that make daily operations safer and more predictable. Please use this safety and damage assessment guide to localize your rope’s damage. Contact your Samson representative for further damage assessment assistance.